CNC Technology training prepares for opportunities in numerous industries, despite pandemic

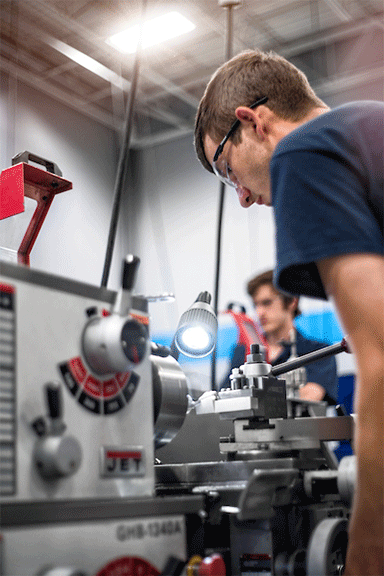

MOORESVILLE, N.C. – Despite the recent jobs report showing the U.S. lost 140,000 jobs in December and continuing record national unemployment, employers across the country are hiring trained Computer Numerical Control (CNC) machinists, and recent graduates of the CNC Technology program at Universal Technical Institute’s (UTI) Mooresville, N.C. campus, NASCAR Technical Institute (NASCAR Tech), are well prepared to start fulfilling high-tech careers.

According to a recent case study by the Iredell County Economic Development Corporation, UTI’s CNC program and industry partners like Roush Yates and Mitsubishi Materials USA are shaping the regions’ automotive industry. UTI has graduated 250 CNC Machinists since the 36-week program’s inception in August 2017. Graduates can seek career opportunities in a myriad of industries, including in the automotive, motorsports, aerospace, defense and medical fields.

Wyatt Pearson, who graduated from the CNC Technology program after the COVID-19 pandemic began, said he knew demand for machinists was still high, but he was surprised that he had multiple offers from manufacturing companies in the Charlotte, N.C.-area in spring of 2020. He currently works as an operator at Compaero, which manufactures parts for aerospace and defense.

“So many businesses and companies have shut down, but the country can’t run without manufacturing,” said Pearson. “Manufacturers are the ones the country relied on when the pandemic hit. We’re an essential business and demand has been steady for our products. When you have a skill like this, you have it for life, and the knowledge I acquired at NASCAR Tech can serve me in many different industries.”

In the last several months, recent graduates have also started careers with national and global manufacturers such as Ingersoll Rand, Maclean-Fogg, Wakefield-Vette and Roush Yates Manufacturing Solutions. UTI graduate Charles Hilliard said his company, Revmax Torque Convertors in Charlotte, N.C., has had one of its best years yet. He began working there as a CNC machinist in the summer of 2020, producing parts for diesel transmissions.

In the last several months, recent graduates have also started careers with national and global manufacturers such as Ingersoll Rand, Maclean-Fogg, Wakefield-Vette and Roush Yates Manufacturing Solutions. UTI graduate Charles Hilliard said his company, Revmax Torque Convertors in Charlotte, N.C., has had one of its best years yet. He began working there as a CNC machinist in the summer of 2020, producing parts for diesel transmissions.

“Even if the economy slows down and people lose their jobs, there are still necessities like keeping our vehicles running,” said Hilliard. “I absolutely love my job, and if we weren’t working, we wouldn’t be able to keep people on the road.”

NASCAR Cup Champion Brad Keselowski has been hiring at Statesville, N.C.-based Keselowski Advanced Manufacturing (KAM) throughout the pandemic too, and is known to call on NASCAR Tech to fill open positions at his company. He praises their graduates as professional, passionate machinists.

“The specialized, condensed curriculum that NASCAR Tech students are exposed to prepares them for entry-level positions at KAM. Advanced manufacturing is a fast-moving, ever-evolving industry, and KAM sits at the forefront of many initiatives driving Industry 4.0 Manufacturing into the future,” said Keselowski. “Unfortunately, our country has faced a deficit of talent entering skilled trades over the recent past. Now more than ever, as COVID-19 has exposed supply chain weaknesses worldwide, our country is going to look from within to emerge at the forefront of manufacturing, and we know that NASCAR Tech graduates are prepared for the intense, rapid innovation of advanced manufacturing.”

For more information:

A virtual, live tour and information session on NASCAR Tech’s CNC Machining program will be offered on Saturday, January 30 at noon EST. The session will feature Roush Yates Manufacturing and participants will see the equipment used in CNC Machining, hear about the job opportunities and industries open to machinists and learn about the scholarships, grants, employment assistance and career support available through NASCAR Tech. Visit http://bit.ly/UTIcnc02 to register for this complimentary online session.

###

About Universal Technical Institute, Inc.

With more than 220,000 graduates in its 55-year history, Universal Technical Institute, Inc. (NYSE: UTI) is the nation’s leading provider of technical training for automotive, diesel, collision repair, motorcycle and marine technicians, and offers welding technology and computer numerical control (CNC) machining programs. The company has built partnerships with industry leaders, outfits its state-of-the-industry facilities with current technology, and delivers training that is aligned with employer needs. Through its network of 12 campuses nationwide, UTI offers post-secondary programs under the banner of several well-known brands, including Universal Technical Institute (UTI), Motorcycle Mechanics Institute and Marine Mechanics Institute (MMI) and NASCAR Technical Institute (NASCAR Tech). The company is headquartered in Phoenix, Arizona.

For more information, visit www.uti.edu. Like UTI on www.facebook.com/UTI or follow UTI on Twitter @UTITweet, @MMITweet, and @NASCARTechUTI.

About NASCAR Tech:

Along with the CNC Machining Technology program, NASCAR Tech’s Mooresville, N.C. campus also offers the Universal Technical Institute core automotive training program, Manufacturer-Specific Advanced Training with Ford, Nissan and Mopar, and an optional 15-week elective to train students for a career in motorsports, including hands-on training in engines, fabrication, welding, aerodynamics and pit crew essentials. Through NASCAR Tech’s elite Spec Engine program, select students have the opportunity to build engines that will compete in NASCAR-sanctioned races.

Media Contact:

Faye Shroff

Breaking Limits for NASCAR Technical Institute

fshroff@breakinglimits.net

(704) 591-4353